Change the Process – Reduce the Weight

Endurance Technologies Ltd, Pune, is one of India’s leading aluminum die casting companies which provides complete solutions for cast wheel, suspension, transmission and brake products. Endurance Technologies has received the “Best Casting Award” at Alucast 2010 for its flywheel housing casting.

The flywheel housing, an essential part of an engine, is mounted on the fly- wheel to act as a cover and to accommodate various other components such as the starter motor, etc. The main requirement for the part is a robust construction, as the flywheel has to withstand vibrations produced by the engine. With the aid of MAGMASOFT®, Endurance Technologies has developed this component to fulfill the customer's requirements. In cooperation with the OEM design team, Endurance modified the product design and also changed the production process from gravity die casting to high pressure die casting. The cast-ing weight was reduced from 9.5 to 7 kg and the runner and gating system was also optimized with the help of MAGMASOFT® simulations.

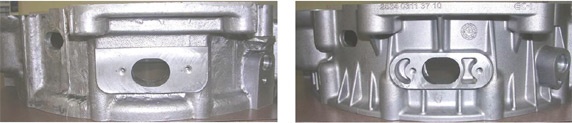

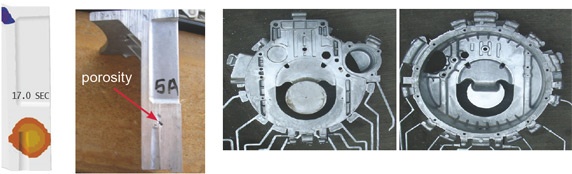

Product design study at Endurance: At the beginning of the project, a prototype sample casting was provided by the customer which weighed 9.5 kg with a minimum wall thickness of 10 mm. The Endurance engineers' first objective was to reduce the casting weight and optimize the process productivity. To fulfill this requirement, the casting design had to be modified after studying the solidification pattern using MAGMASOFT® simulations. Although the original prototype sample was produced in a gravity die casting process, Endurance proposed to change the manufacturing process to high pressure die casting. After general approval, the casting model was jointly modified to meet the manufacturing requirements of the HPDC process. Using MAGMASOFT® simulations, the casting weight could be reduced by 2.5 kg by minimizing wall thickness and mass accumulations at pockets and ribs in appropriate areas.

Changing the manufacturing process to high pressure die casting led to increased productivity through to cycle time reduction as well as handling and machining of the component. The cast weight was reduced without affecting the properties and functional requirements. There was no requirement for a T6 heat treatment of the part and supply chain lead time was reduced, which led to increased volumes.

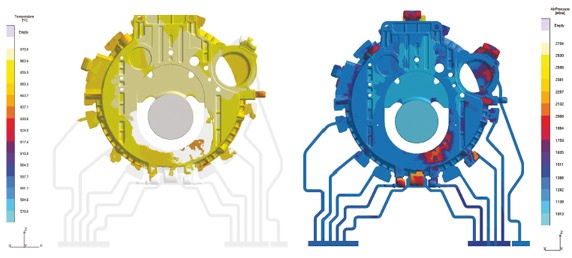

MAGMASOFT® result analysis helped in tool design optimization: MAGMASOFT® is used in the development of gating systems for all components produced at Endurance. For the flywheel housing casting, a center runner and gating system was proposed. Various gating system alternatives were created in CAD and then evaluated by means of simulation studies. Through the optimization of the runner design and the orientation of the casting, it was possible to control the temperature drop of the metal without changing the die filling time. The MAGMASOFT® filling results also helped in finding the best positions for vents and overflows. In particular, the AirPressure results were used for this purpose.

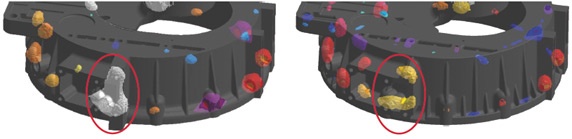

Using the MAGMASOFT® solidification results, local hot spots could be used to identify critical mass accumulations. The hot spots indicate the duration of local solidification and can therefore be used to find areas in danger of shrinkage porosity. The gating system was optimized for maximal feeding through directional solidification. Furthermore, the cooling system was optimized by studying the thermal balance of the die and its effect on the solidification.

After conducting T-0 trials, casting defects which could not be fully removed in the early stages were correlated with MAGMASOFT® results and consequently optimized by process improvements. The solutions were put in place before sample submission to the customer. T-1 samples given to the customer were validated and approved without any changes in product and tool design.

This part has been in production since August 2010 and has replaced a gravity die casting part in the engine assembly. This has helped the casting user to reduce its supply chain lead time and increase volume with a reduced engine weight. This product is considered as a benchmark in the automotive industry, by creating a new methodology to introduce process changes and weight reduction without affecting functional requirements.