Big is Beautiful

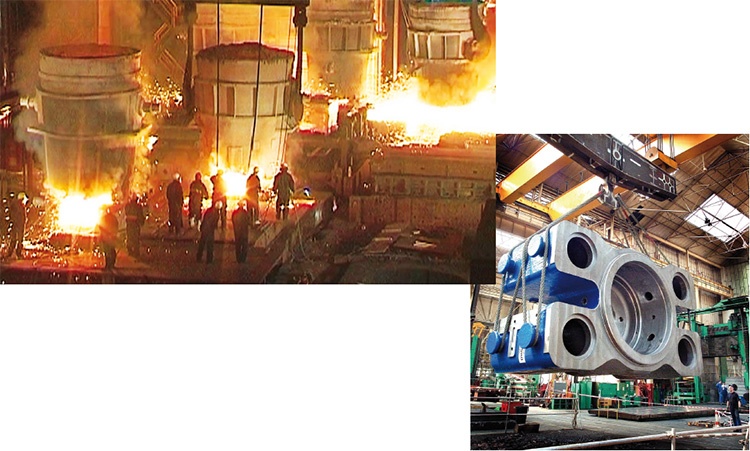

There may have been bigger pour weight castings made, but 600 tonnes of liquid steel to make a 340 tonne finished weight casting is not an everyday job by anyone’s standards. Sheffield Forgemasters International Ltd. of Sheffield England, is known worldwide for its ability to engineer very large cast products and the enquiry from an existing customer, SMS Meer in Germany for two 340 tonne screw press parts was not an everyday occurrence.

Making such large parts requires every stage of the casting process that sand founders are familiar with to be carried out on a very large scale. One of the finished parts was 7.5 x 4 x 3m.

Patterns and moulds have to be made of this incredible size. The melting facilities have to be capable of melting 600 tonnes of liquid steel and controlling secondary steel making and ladle conditions to make all the steel available for pouring at the right temperature at one time. The considerable efforts in pattern, core, mould and steel preparation culminate in the pour. Ladle layout and casting parameters are determined to provide a fast smooth mould fill. 50 tonnes of steel enter the mould in the first 15 seconds and the filling is complete in minutes. The logistics involved in lifting the casting from the moulding pit and transporting it between facilities and to their machine shop required the use of specialist lifting equipment to combine the lifting power of their two huge cranes and a multi axel 72 wheel low loading trailer.

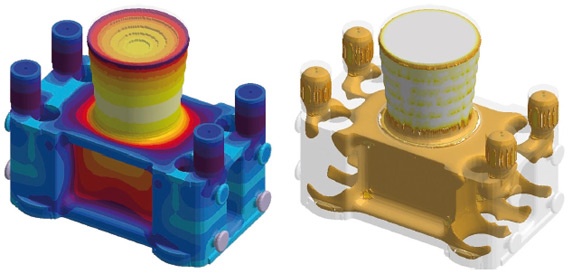

In dealing with such large castings, the transportation restrictions are important and have as much as anything else limited the maximum casting size and weight. With this size of casting there is no sampling or percentage scrap rate. Along with many other casting manufacturers Sheffield Forgemasters has long used MAGMASOFT® to develop a method before cutting the pattern or even quoting.

MAGMASOFT® is applied routinely along with the company’s decades of experience to explore all possible methoding options. On these large castings the use of MAGMASOFT® ensures that the desired casting quality is met within the many limitations imposed by the practicalities of the moulding, feeder head removal, lifting, heat treatment, handling and transportation.

Once Sheffield Forgemasters had made the castings, sound on time and to the customer’s technical and commercial requirements and SMS Meer constructed the mammoth 35,500 tonne screw press, the end user Böhler steel can now efficiently forge larger parts than ever. This casting was the first and has paved the way for several follow on contracts for similar sized components. Making such unique castings is always going to be a challenge, but if they are right first time, then big is most definitely beautiful.