“Global Partner – Local Commitment”

There is reason to Alteams' slogan "Global Partners - Local Commitment". Despite the fact that the volume production at the Swedish foundry Alteams Stilexo has moved away, Alteams Group is still one of the largest light metal foundry groups in the Nordic region. In addition to this, Alteams Group has a rapidly growing business in India and China.

Alteams Group, which is owned by the Finnish recycling group Kuusakoski, has its activities divided into two customer segments: NET (Communication Networks) and MET (Mechatronics). The common denominator is cast aluminum, produced in die casting, permanent mold, sand casting and rheocasting processes. Alteams Group has a total of about 50 casting machines with clamping forces from 160 to 2200 tons and realizes a turnover of EUR 100 million (2010) with a total of 1500 employees in Sweden, Finland, China, India and Estonia.

Sales and Technology Center in Sweden - Alteams Stilexo

Today there are currently five people working at the company Alteams Stilexo, which is located in Skillingaryd in the Småland region. This location is a very important hub in the Alteams Group, due to the proximity to the major telecommunications customers and is an excellence center for sales and engineering within the Alteams Group.

The site manager, Daniel Eklund, is also responsible for eighteen employees at Alteams Eesti in Estonia, where Alteams Group has its hub for the supply of castings within Europe. Working fully in line with the company’s slogan, he emphasizes that they are running the projects locally, but with a global anchorage. This means that methoding and engineering is done in Skillingaryd, while the actual production is placed where it fits the best. In this way, the customer is given a greater ability to reach the market with their products in the shortest possible time.

In the work on casting methoding, tooling design or geometrical adoption for casting, casting simulation has been an indispensable tool since 2003, when Alteams Stilexo invested in its first licenses of MAGMASOFT® and MAGMAhpdc. Today, simulation results are also very important as a basis for discussions with customers during early stages of projects. Occasionally, Alteams Stilexo also supports the factories in China, India and Finland with simulation services. The expertise of the team in Skillingaryd also includes skills in mechanical design, CAD/CAM, CNC, automation, gasket dispensing and last but not least logistics, which of course is a key issue for the chosen approach. To secure the production before producing the series tooling, Alteams often starts by producing a prototype tool, i.e. a soft tool to run a limited number of shots for evaluation and verification purposes. Typically, Swedish tool makers are contracted for soft tool manufacturing. Minor tool adjustments are normally made in Skillingaryd where up-todate CNC machines ensure fast service. In this way, very rapid test results and short lead times are obtained, as well as resulting in cost savings for the customers in the end.

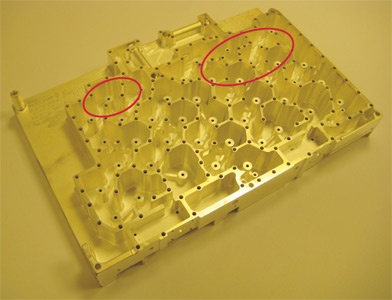

In the NET segment, a large number of new products are introduced every year, and as stated above, simulation using MAGMASOFT® plays a vital role in various stages of the projects - all the way from initial discussions with customers to fine tuning the production and problem solving. A typical product is a so-called cavity filter (figure 1), which is used for filtering the signals in base stations for mobile phone communication. The geometrical complexity is high, and in addition, there is also a large need for machining. In many cases more than 100 holes need to be drilled and threaded. Therefore, the requirementsto minimize the pore content and to increase the overall quality are very high.

In the casting, the foundry initially experienced problems with air being trapped during cavity filling in the indicated areas. It is difficult to efficiently vent these areas even though a limited amount of air can escape through loose ejector pins. The metal was pre-filling the casting along the edges, and this trapped air into the two critical areas at the moment when the vacuum connections were closed.

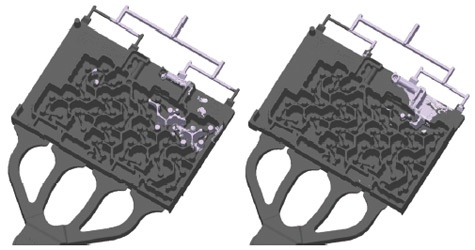

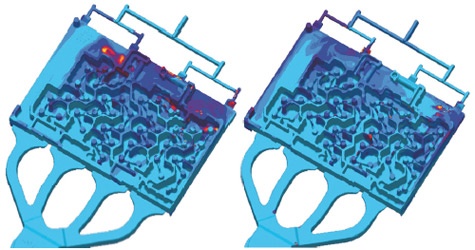

The problem was quickly and efficiently solved by blocking part of the two outer gates on each side, resulting in a more condensed flow and less trapped air. Figure 2 shows where air is trapped at a very late stage of filling, before (left) and after (right) the gating modification. In the modified tool, the remaining air shown has a good chance to escape through the adjacent vacuum channel, which is still open. The calculated amount of trapped air in the casting at completed filling is shown in figure 3 for both versions. Obviously, the modification had the expected impact on quality, which was also proven in the foundry. It should be noted that any possible air escape via loose ejector pins was neglected in the simulation, leading to a somewhat higher amount of trapped air in some areas as compared to the real castings.

MAGMASOFT® is today used extensively at Alteams Stilexo as well as at all Alteams Group production sites in Finland, China and India.