Solving Casting Surface Defects

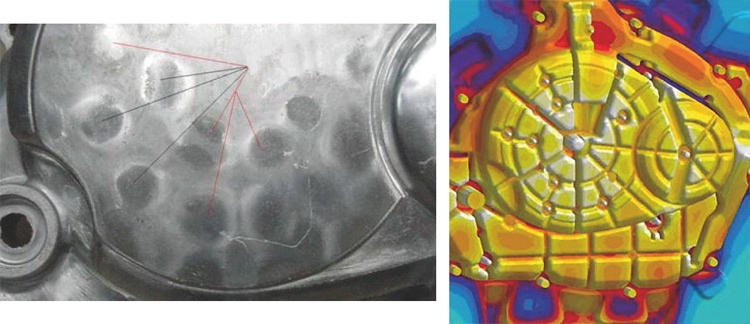

The surface of a die casting suffered from peeling or had two-tone discolorations. Sometimes a second buffing was required to eliminate these surface problems.

Simulation indicated that the die was being overheated to more than 450° C in several locations. This led to soldering of the part to the die, which was the reason for the surface defects. Based on these results different measures were taken. In particular the designers were encouraged to revise their design by increasing the wall thickness in the critical location by 0.5 - 0.65 mm.

Engineering

Support