Simulation Project at the University

MAGMASOFT® in engineering education? Yes, of course! Due to the active support of MAGMA, the engineering students at Georg-Simon-Ohm University in Nuremberg can now simulate the casting process with MAGMASOFT®.

Because MAGMASOFT® can be used easily and intuitively, the students are able to start with their own first simulations almost immediately, after a minimum of instruction. The application helps to clearly illustrate important relationships between the geometry of the component and the mold as well as the process parameters. With the help of MAGMASOFT®, the integration of different CAE tools within the development process is demonstrated to the students.

Instructed by Prof. von Grossmann and Prof. Hornfeck, a student group had the task to develop a two-cylinder model engine with integrated water cooling and to produce initial components. Beside the CAD- and CAE-software and a rapid prototyping wax thermal printer, Georg-Simon-Ohm University also has facilities for investment casting.

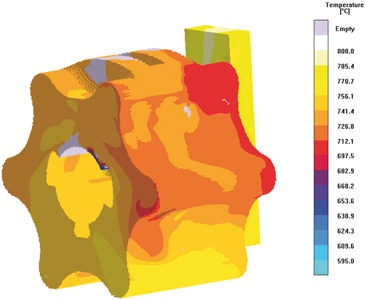

Full of energy and with many good ideas, the group started with the engine’s construction. Promptly the first problems occurred, which are also known to experienced engineers in practice - communication between design engineers and foundry turned out to be a problem. The tough timeline of approximately 10 weeks did not appear to be possible. Only with the introduction of a project manager was the project steered onto the right track and first prototypes could be poured as vacuum supported precision plaster castings. The simulations with MAGMASOFT® helped the students, who were inexperienced in foundry technology, to optimize the gating system and to analyze potential sources of problems such as hotspots.

In conclusion, this was a very educational and instructive experience for all that were involved. Further projects will surely follow as more possibilities for optimization are already under consideration.