C+M Workshop

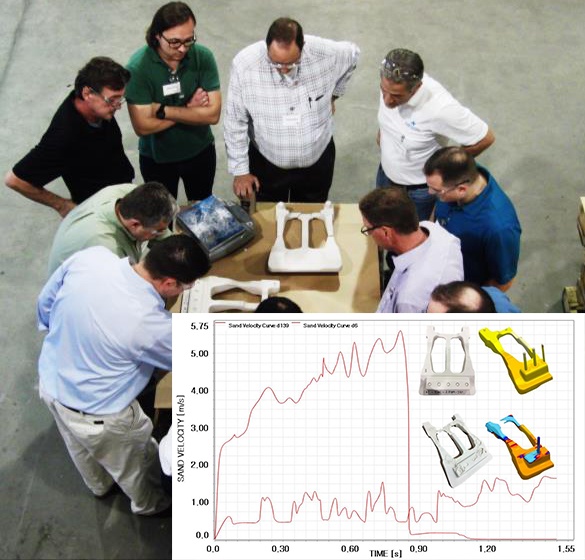

This workshop is a hands-on core making program. Attendees will be interacting with coremaking equipment and machinery. Machine operation variables, core sand variables, and binder variables will be investigated. Additionally, the attendees will gain a better understanding on how factors like: tooling, sand characteristics, shooting, blowing and venting layouts play important roles in the quality of sand cores, and in turn, influence

the quality of metal castings.

Contents:

• The theory and principles of chemically bonded coremaking

• The interaction of tooling and coremaking equipment

• Using the MAGMAC+M optimization tool

• How to apply the MAGMA APPROACH and production methods in optimizations

This workshop will begin with technical discussions surrounding core shooting, core hardening, tool design, vent types, nozzle design, and core cavity layout. Attendees will also see how the use of casting process optimization plays a key role in identifying common defects associated with variability in the process. Additional investigation into the technological advances of chemical binder systems will also take place.

The combination of theory, virtual coremaking, and real time variation with actual core equipment dramatically improves an attendee’s understanding of what really matters in the process of making high quality cores. Attendees will be able to apply these concepts to their own core production projects, and in turn, be empowered to create higher quality sandcores.

Our next C+M Workshop will be May 17-18, 2023 in Trussville, AL. Click here to register or contact us for more information.

Contact MAGMAacademy

MAGMA Foundry Technologies, Inc.

10 North Martingale Road

Suite 425

Schaumburg, IL 60173

Phone: 1.847.969.1001

Show email