Detailed Insights Into the Filling Process at Voith

More than a third of the energy generated worldwide by hydropower is produced with turbines and generators made by Voith AG. Every third sheet of paper is produced on a Voith paper mill machine. The group, which originated in southern Germany, also manufactures industrial actuators and braking systems for industrial as well as for train and road applications.

In 1825, Johann Matthäus Voith took over his father’s fitter’s workshop with just 5 employees. In 1830, he was engaged in the construction of a paper mill machine with Johann Jakob Widmann, industrial pioneer and founder of the German paper machine industry. Today, Voith is one of the larger family owned companies in Europe, with 37.000 employees and more than 270 operating sites.

The only foundry in the group, located in Brazil near Sao Paolo, is a driving force for casting innovations. Consequently, the foundry has been using MAGMASOFT® for casting optimization for more than 12 years. The Voith foundry is known for its competence and quality in making carbon and stainless steel castings, gray and ductile iron. In Latin America, the foundry is also the largest manufacturer of hydropower components, with recognized references as a supplier of strategic cast components for power plants all over the world – amongst them for Itaipu, Brazil/Paraguay and Three Gorges project in China. For a 12 ton Kaplan blade, Voith originally only performed a solidification simulation. The results did not indicate any critical defects.

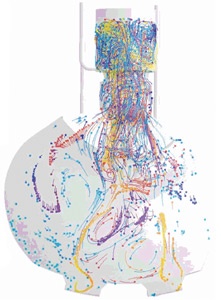

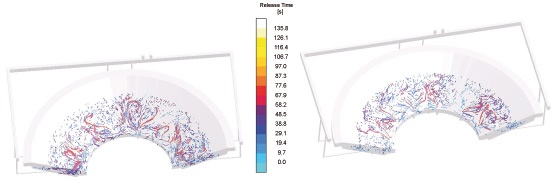

In addition to the evaluation of temperatures, velocities and pressures, the dynamics of mold filling can effectively be investigated using the MAGMASOFT® tracer particle function. The more effort the casting requires and the more risk that are involved, the more useful this functionality will be in helping to identify potential flow defects. Tracer results offer the user a tool to identify the location and intensity of turbulent zones during the flow. They show critical areas where slag inclusions might be expected and allow a correlation with flow driven erosion problems in the casting or the gating system.

With the support of the flow simulation of the Kaplan blade, turbulence could be identified as causes for the surface defects. Consequently, further simulations were performed for alternative gating designs, finally resulting in strongly reduced inclusions in the real casting.

Today, the Voith foundry uses mold filling simulation as a standard, also for heavy sectioned castings.