Probalistic Property Modeling for Reliable Casting Design and Production

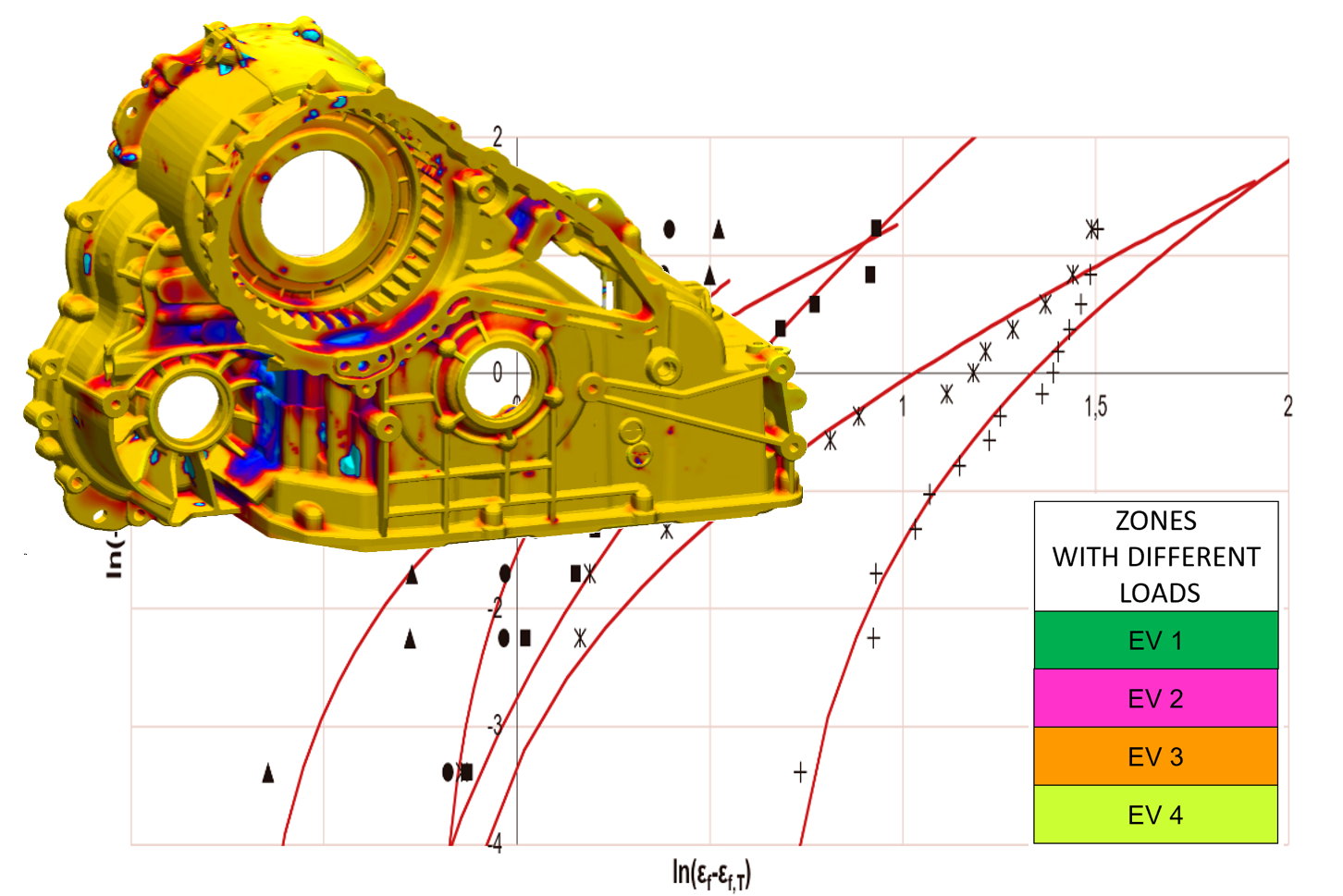

A new patent-pending methodology developed by MAGMA leverages the possibilities of virtual casting process simulation of MAGMASOFT® to predict a statistical distribution of local mechanical properties based on calculated local microstructures and defects. The large result sets from each individual simulation can be used and statistically analyzed in the same way as numerous individual tensile tests. By incorporating a process variability into the simulation, this innovative approach enables probabilistic modeling of expected local properties. Consequently, this method supports designers during the design phase for reliable component development and assists foundries in achieving robust process designs.

Engineering

Support