What's New in MAGMAlpdc incl. CPC & MAGMAwheel?

What's New in MAGMAlpdc & MAGMAwheel?

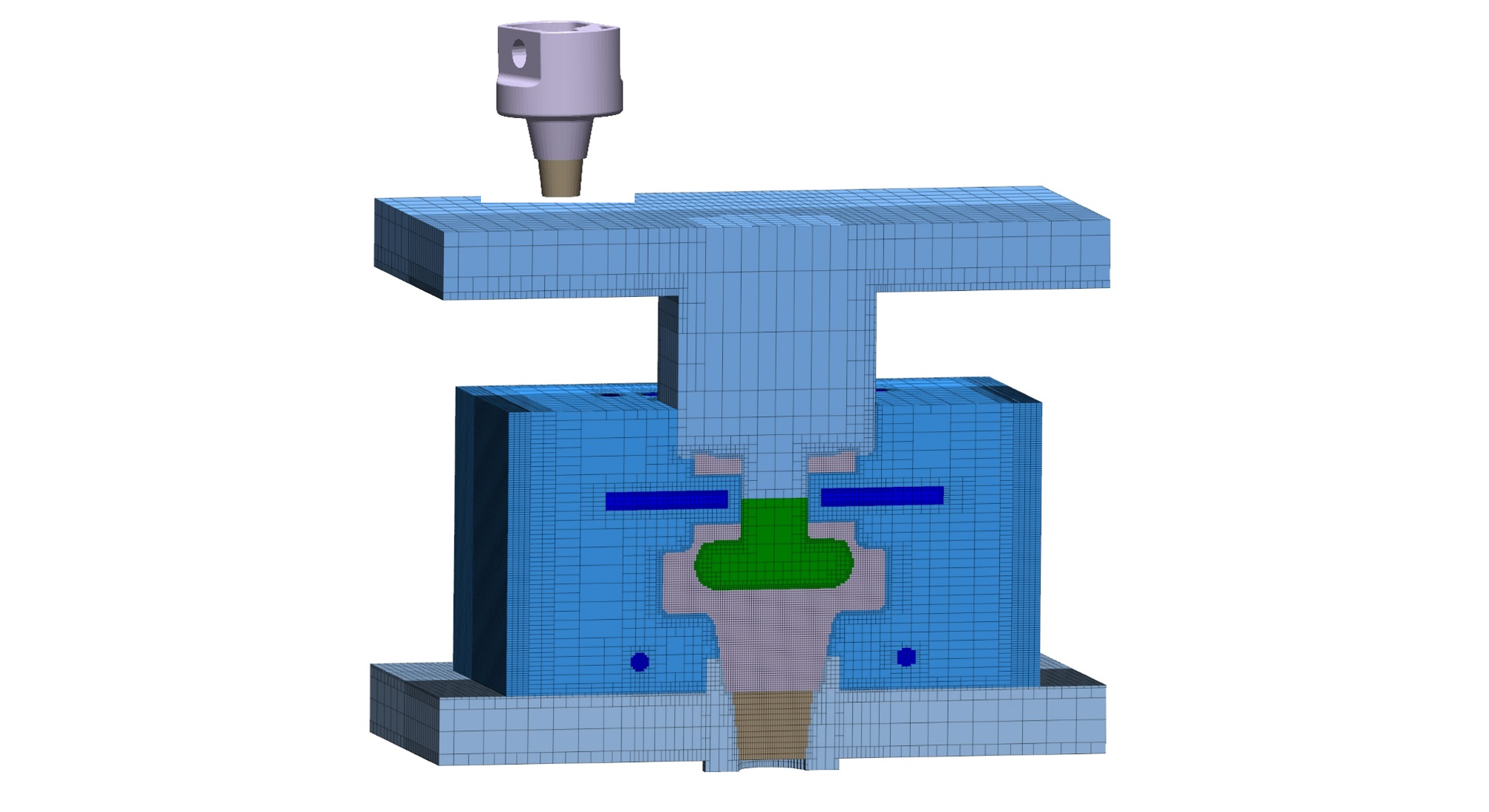

With MAGMASOFT® 6.1, users benefit from comprehensive innovations in the simulation of low pressure die casting processes. The integrated new solver technologies and the optimized mesh generation with composite and TAG meshes (True Adaptive Geometry Meshes), which have already proven themselves in core production, high pressure die casting and permanent mold casting, enable a more precise and efficient mapping of complex casting processes.

The newly introduced 'Heat-up Phase' functionality supports the preheating of permanent molds by integrating electric heating cartridges with PI control and Variotherm temperature control.

In addition, the new 'Tracer' results provide deeper insights into the temperature, velocity, pressure and path length of the melt. A new 'Air' result also facilitates the identification and evaluation of air entrapments in the casting.

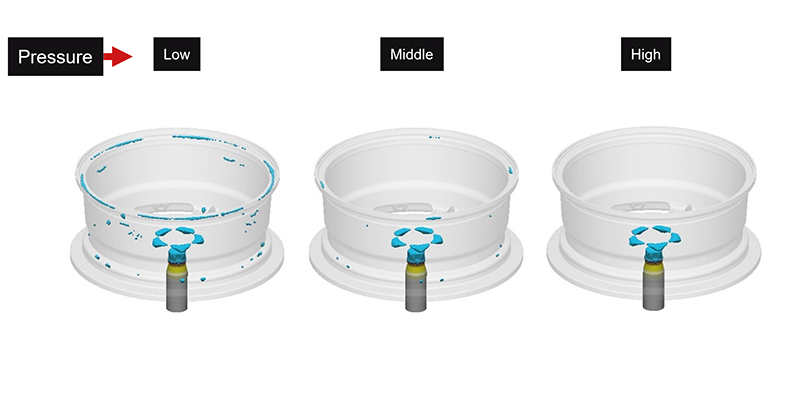

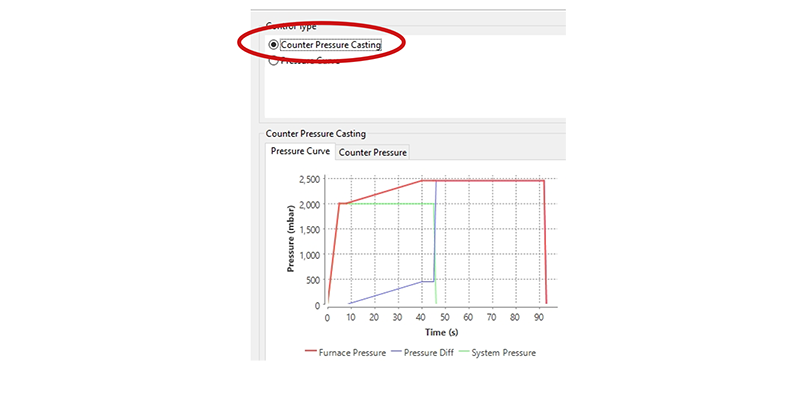

For the counter-pressure casting (CPC) process, a special enhancement is now available, allowing the accurate definition and simulation of process parameters such as counter-pressure and pressure difference. This enables a detailed analysis of the influence on both feeding and mechanical properties.

Highlights:

- New solver technologies: To map complex casting processes both precisely and efficiently, solver technologies are used that have already proven themselves in high pressure die casting, permanent mold casting and core production.

- Extended mesh generation: integration of composite and True Adaptive Geometry (TAG) meshes for accurate geometry and process mapping

- Heating phase: heating of the permanent mold with electric heating cartridges with PI control and Variotherm temperature control

- Additional 'Tracer' results: in-depth insights into temperature, velocity and pressure of the melt as well as path length analysis

- Identification of air entrapments: New "air" results support the evaluation of air entrapments in the casting.

- Dedicated CPC extension: specific definition of process parameters and simulation for the counter-pressure casting process

- MAGMAlpdc and MAGMAwheel: innovations to take into account surface tension, pressure influence on feeding, flow in temperature control channels and electrical heating systems

- Extended prediction capabilities: analysis of turbulence, air entrapments, feeding-related porosity and local heat flows

Latest Publication

MAGMASOFT® 6.1 – Efficient Optimization of Processes and Profitability

With new functionalities and extensive enhancements, MAGMASOFT® 6.1 offers comprehensive support for optimizing low pressure die casting processes and facilitates the design of die-cast parts. A specially developed process module for rheocasting and thixomolding processes adds numerous new options for users in core production and continuous casting.

In addition, the newly introduced ECONOMICS Perspective enables, for the first time, a quantitative evaluation and optimization of both costs and CO₂ emissions for all simulation projects, improving both the profitability and the sustainability of all applications.

System Requirements

MAGMASOFT® is available for all suitable current operating systems such as Linux and Windows. MAGMASOFT® can be used on multi-processor computers or massively parallel on cluster computers.