Casting Distortions During Solution Treatment

Aluminum castings are often heat-treated to increase mechanical properties and simultaneously decrease thermal stresses induced by the casting process. The heat treatment process consists of 3 steps. First is solution treatment, where the part is heated to a temperature near the solidus temperature of the alloy. Next the part is quenched, which is a fast cooling, commonly in water. Finally an artificial ageing is performed, where the part develop its mechanical properties and where stresses are relaxed.

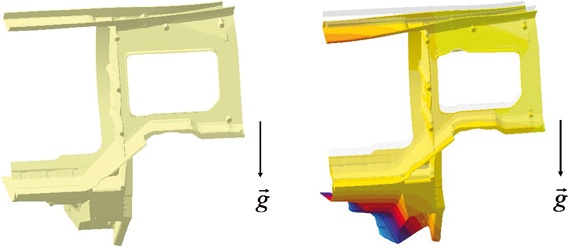

Due to thin wall thicknesses, solution treatment is the critical heat treatment process step for aluminum structural parts. Depending on the layout of the supports for the casting, gravity may have a huge influence on deformation of the component. On the right hand side, the undistorted part is hanging vertically before solution treatment. During heating, the part deforms due to gravity. At the end of heating, the overall distortion of the part averages 4.5 mm (right picture). Here the undeformed part is also shown as transparent.

* Courtesy of Volkswagen AG, Germany