Our headquarters has moved!

It’s no simulation - We have really moved!

Our new state-of-the art headquarters are now fully operational and offer a new quality of work!

The new facilities just across the street accommodate all employees of MAGMA and our sister company SIGMA.

This milestone is another step in keeping ourselves fit for the future.

We look forward to welcoming you at our new offices:

Kackertstraße 16 – 18

52072 Aachen

Germany

Please note that our shipping and billing address and contact details including phone numbers have changed.

Please update your records to replace our previous address: Kackertstraße 11, DE-52072 Aachen, with our new address:

MAGMA Gießereitechnologie GmbH, Kackertstraße 16-18, DE-52072 Aachen

With the understanding that ultimately their customer was seeking to provide a quality product to their customer Smith had a conference call and discussed the concerns and challenges with changing the standards and expectations for quality and inspection after the castings had already been produced. The customer was understanding but still wanted to see that their castings meet the desired quality. It was agreed that Smith would share the casting simulation results in an effort to alleviate any concerns and demonstrate the integrity of the castings that were produced.

Additionally, Smith directed their customer to an article published in the International Journal of Cast Metals Research, 2001 “Analysis of ASTM X-ray Shrinkage Rating for Steel Castings”. This article states and assess the capabilities of x-ray inspection. Smith’s experience with x-ray inspection has varied; there have been instances where x-ray is dead-on, and other instances where shrinkage was truly present in a casting but not initially identified until cut-sectioned, and still other circumstances where x-ray identified a concern but when cut sectioned, the issue did not exist in the casting. X-ray is a useful tool within the known inherent limitations.

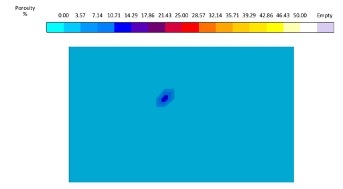

As promised, a presentation of all the pertinent MAGMASOFT® simulation results was compiled and provided to the customer. These results demonstrated that the castings would meet the soundness quality requirement they were seeking. Shrinkage porosity was present in two locations of the castings but at levels within the allowable limit of the x-ray specification they would have otherwise utilized.

After review of the simulation results, and provided X-ray inspection article, Smith’s customer agreed to forgo the x-ray inspection request and move forward with the castings, as produced. The collaboration between parties, use of research already conducted, and the insight MAGMASOFT® provided enabled a quick resolution to a challenge that devoid of simulation insights would likely have stalled and sputtered for an undetermined amount of time.

Smith Castings, LLC is a foundry located in Kingsford, MI producing steel and iron castings. They specialize in short-run orders with responsive lead times, whether you need on piece or hundreds. They serve a variety of industries including agriculture, construction/heavy equipment, railroad, defense, mining as well as oil and gas. Smith believes in the philosophy that, “Coming together is a beginning; keeping together is progress; working together is success”. – Edward Everette Hale.