MAGMA otorga gran importancia a las alianzas intensivas con universidades e institutos de investigación líderes y participa activamente en una serie de proyectos de investigación nacionales e internacionales.

From Research and Development

Within Projects

History of Selected Projects

MaBIFF: "Dimension-reduced component properties through the integration of production and functional simulation"

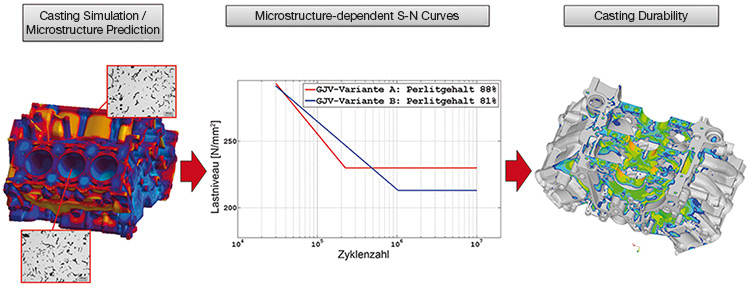

The aim of the research project MaBiFF was to assess the influence of different microstructural features in cast iron (GJS-400 and GJV-450), which can be locally predicted using casting process simulation, on durability. For this purpose, S-N curves were determined for varying microstructures from extensive tests, enabling the creation of a closed chain considering the manufacturing parameters through the calculated local microstructures up to a prediction of the local durability. This makes the transfer of the influence of the manufacturing process in operational fatigue calculations possible.

Within the scope of the MaBIFF project, the prediction of local microstructures was extended. For this purpose, MAGMA developed a calculation procedure in which process simulation was integrated into computational fatigue calculations. A correlation between the local durability and the local microstructure was determined. In addition, the necessary interfaces for data exchange with programs for fatigue life calculation (for example, FEMFAT, LMS Virtual Lab Durability) were created. This makes it possible to calculate the expected durability for the materials GJS-400 and GJV-450 based on a casting simulation and to transfer this information as input for durability calculations.

This research and development project was funded by the Federal Ministry of Education and Research (BMBF) under the funding code 01RI0713 and was supervised by the German Aerospace Center (DLR) in Bonn. The project was carried out as a joint project between 01.08.2007 and 31.03.2011.

Project partners in this project were Audi AG, Eisenwerk Brühl GmbH, Meuselwitz Guss GmbH and Walter Hundhausen GmbH, Fraunhofer Institute for Operational Strength and System Reliability LBF, Fraunhofer Institute for Technological and Economic Mathematics ITWM, Germanischer Lloyd Industrial Services GmbH, Institute of Foundry Technology IFG and MAGMA Gießereitechnologie GmbH .

A detailed project summary can be found here: Bundesministerium für Bildung und Forschung.

The Music Project was aimed at developing a “MUlti-layers control & cognitive System to drive metal and plastic production line for Injected Components“ under the EU Factory of the Future initiative, targeted at improving efficiency, adaptability and sustainability of manufacturing systems as well as their better integration within business processes in an increasingly globalized industrial context.

This ambitious and challenging goal can support High Pressure Die Casting and Plastic Injection Molding Companies in achieving lower scrap generation, higher efficiency and robustness, and minimize energy consumption.

The idea behind the project was to link the new Control and Cognitive system to real-time monitoring for an active quality control.

One objective of MAGMA in the project was to improve the quality prediction of the high pressure die castings with simulation. New criteria for the simulation were developed and validated with the help of a “horse shoe” test geometry. At the end, also real demonstrator components like a shock tower from the partner Audi were used to apply the generated know-how.

For such a Meta-model to be realized, numerous experimental data were generated, and MAGMA additionally added virtual experiments (DoE), with varying process parameters and their influence on the casting quality, to train the Meta-model before foundry trials started..

More information can be found on the project website: http://music.eucoord.com

In addition a booklet is available, which summarizes the main results of the project:

“Smart Control and Cognitive System applied to the HPDC Foundry 4.0”

Edited by Nicola Gramegna and Franco Bonollo, Assomet Servizi Srl, Enginsoft SpA

ISBN 978-88-87786-11-8

Process Optimization for Additive Manufacturing in the CustoMat 3D Project

Additive manufacturing processes are catalysts for technological innovations. The possibility of being able to use more complex geometries – that is, three-dimensional structures with undercuts or hollows –, allows finding innovative solutions for the continuously growing customer demands and implementing them in prototypes or very small series.

Remarkable progress is observed in particular in the development of new, complex component designs – accurately designed . This also has a positive impact on the automotive industry: Until now, producing castings with such complex geometries by using conventional technologies, such as milling, turning or casting, was usually not possible at all or disproportionally costly.

As part of the BMBF-funded research project "CustoMat 3D", the EDAG Group, Daimler AG and seven other project partners have developed an aluminum alloy for structural components that is able to give higher strength as well as higher breaking elongation. The latter is particularly important for crash performance. This constitutes a progress, as until now, the aluminum alloys available for additive manufacturing processes were not able to meet the required mechanical properties.

Over the past three years, the entire process chain from alloy powder production to simulation, up to the development of components was analyzed. In this context, the task of MAGMA GmbH was the development of models for the virtual optimization of the direct metal laser melting process. The focus is on preventing defects already in the component/process development.

In an interview, MAGMA's project coordinators talk about additive manufacturing and the decisive role the early simulation with MAGMASOFT® plays in this context.

Dr. Hartmann, how did the cooperation with EDAG come about?

Cooperating with EDAG was not new to us. We had already successfully worked together in the field of structural castings in the past. Dr. Martin Hillebrecht, Head of the Competence Centre for Lightweight Design, Materials & Technologies at EDAG approached us with the intention of developing a new AM process specifically for automotive structural components. For innovative materials or manufacturing processes to be established in the automotive sector today, usually, a verified, virtual process chain needs to be established.

Dr. Thorborg and Dr. Esser, what development tasks were you and your team faced with?

The greatest challenge in modeling powder bed AM processes (SLM, LPBF, etc.) lies in resolving the details around the movable heat source (laser) and simultaneously calculating temperature, stresses and full-size distortions in the casting. This means that information needs to be processed on different length scales, starting with micrometers for fine metal powder and the melt pool near the laser beam, up to centimeters on component level. Our main task was to find suitable mathematical models for accurately describing the printing process, that is, the laser movement, the corresponding temperature increase and the stresses resulting from the rapid cooling.

What were the challenges that you encountered?

Just like in welding, very high temperatures occur in a small zone surrounding the melt pool – compared to the cold material in the remaining component. Depending on the design and process conditions, these great temperature differences may lead to high stresses. This generally harbors the risk of cracks or later distortions of the part when the base plate and the supporting structure are removed. Predicting these problems and the resulting approaches to solving them – such as varying the direction in which the layers are deposited//the layer deposition direction or adding more/other supporting structures –, these were the main problems we had to overcome. So the question was, how can we manage to produce non-critical parts? There is a risk of the parts cracking already during the printing process, detaching from the base plate or distorting to such an extent that they become unusable – that is, dimensional accuracy is no longer guaranteed. Another problem is transferring the information from the mesoscale of the laser that melts the metal powder to the macroscale of the component. For this purpose, we adopted multiscale approaches known from welding simulation. This made it possible to search for critical areas while designing the component and visualize residual stresses as well as distortion of the parts even before production. Thanks to the multiscale approaches adopted, it is also possible to evaluate the stress relaxation during the subsequent heat treatment and thus recognize the effect on the distortions occurring during the removal of the part from the base plate.

Are you happy with the result, Dr. Hartmann?

Our goal was to make sure that the simulation would not run for weeks on end or longer than the printing process itself: Obviously, simulation is meant to optimize the process beforehand so that it can be integrated into the normal work flow of engineers or technicians. There is no time to wait weeks for a result that is needed for the further process. Overnight, at least one variant should be calculated. In the end, our goal was not to scientifically discuss the entire process, but rather to provide engineers with a powerful simulation program for decision-making. The focus is on structuring the calculation in such a way that the computational effort is still profitable, while still enabling the identification of important details under real conditions. We have achieved this as planned within the framework of the project. Following the CustoMat 3D project, the focus will be on validating the models based on extensive results from real, extremely well-documented trials. Thus we can ensure that the calculated predictions are reliable and relevant for both design and process optimization.

What potential do you see for a MAGMA simulation program in the field of additive manufacturing?

This area has considerable potential. We are still going to actively watch the market, connect with potential cooperation partners and continue building on the foundations already laid. Both in polymer injection molding and in high pressure die casting, current discussions center on so-called three-dimensional, near-contour temperature control systems produced through additive manufacturing. This increases the manageability, reliability and profitability of casting process simulation. We are currently sending out invitations to a two-day seminar on "Process and Casting Optimization Through Efficient Die Temperature Control", which will be held in cooperation between the voestalpine Additive Manufacturing Center and MAGMAacademy at the end of November. We are going to discuss new possibilities for virtual design, optimization and realizing such complex temperature control systems.

Efficient process chains for aluminum die casting

The aim of the joint project was to increase the utilization efficiency of energy and resources in the aluminum die casting process chain. The focus of the project was the overall process chain from melting the starting material through the actual casting process, an alloy-dependent heat treatment and machining to the product in the required final quality.

MAGMA has played a central role in the project, since the simulation of the die-casting process can be used to determine and verify decisive measures to increase the utilization efficiency of energy and resources. For this purpose, MAGMA systematically applied MAGMA’s process optimization capabilities in die casting. The focus of the investigations was the reduction of volume or return material, the minimization of the cycle times, the setting of an optimal spraying process and the increase of tooling life. For this purpose, heat transfer coefficients were also determined on a test stand.

The project was selected by independent experts as part of the BMBF framework "Research for the production of tomorrow" within the "innovation resource efficiency" of the ideas contest "Improving energy efficiency in production technology".

The project was carried out between 01.06.2009 and 31.08.2012.